Supercritical carbon dioxide delivers protective molecules to semiconductor surfaces

A simple, green method that applies a protective coating to semiconductors could help to develop these materials for many applications, from batteries to biosensors.

Silicon forms an oxide layer on its surface when exposed to air or moisture, which can detract from its electronic properties. Adding a 'skin' of molecules to the silicon can provide a physical barrier that prevents oxidation, but forming these monolayers can be tricky, requiring an inert atmosphere and long processing times, or demand the use of potentially harmful organic solvents.

Sreenivasa Reddy Puniredd of the A*STAR Institute of Materials Research and Engineering and colleagues have now developed a new way to deliver the protective molecules using supercritical carbon dioxide (scCO2). Carbon dioxide is converted to scCO2 under high pressure, when it becomes a free-flowing liquid that is chemically inert, inexpensive, and more environmentally-friendly than traditional solvents.

The researchers used scCO2 to carry molecules called alkylthiols, which contain long carbon chains with a sulfur atom at one end. Sulfur forms a stable bond with silicon, while the water-repelling carbon chains make a tightly-packed skin on silicon's surface.

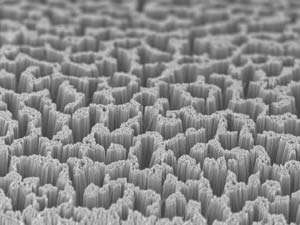

To apply the coating they used alkylthiols containing between seven and 18 carbon atoms to coat silicon, germanium, and silicon nanowires. Each procedure took a few hours, and produced monolayers between 1.6 nanometers and 2.3 nanometers thick that resisted wear and repelled water. The greatest effect was seen for the longest alkylthiol chains.

The monolayers also protected the surface from oxygen for more than 50 days; those prepared using conventional solvents were typically stable for less than seven days. "The increase in stability was expected, but such long-term stability was a surprise," says Puniredd.

Silicon nanowires are being tested for a range of biological applications, including biosensors and antibacterial surfaces. Although fragile and easily damaged by other monolayer formation methods, the silicon nanowires were undamaged by the scCO2 process, allowing the researchers to test how they interacted with human liver cells. Those protected by the 18-carbon alkylthiol significantly reduced cell growth on the nanowires, compared with unprotected nanowires or a flat silicon surface. This is probably because the cells' proteins could not latch on to the monolayer's long carbon chains.

"This scCO2 technology can be adopted for many kinds of inorganic surface modification," says Puniredd. "The technology is not only scalable, but also enhances the quality and stability of the film. It can potentially replace billions of pounds of organic solvents used every year in thin-film fabrication and cleaning applications."

More information: Bhavesh Bhartia et al. Highly Stable Bonding of Thiol Monolayers to Hydrogen-Terminated Si via Supercritical Carbon Dioxide: Toward a Super Hydrophobic and Bioresistant Surface, ACS Applied Materials & Interfaces (2016). DOI: 10.1021/acsami.6b06018

Journal information: ACS Applied Materials and Interfaces